Laser cutting of metal

Laser cutting of metal

One of the most high-quality, fast and inexpensive ways to cut metal products is laser cutting. This technology allows you to accurately process any metal. It eliminates the mechanical impact on the material, thereby preventing its deformation. Thanks to a powerful laser beam (a beam of light) in the size of tenths of a millimeter, a neat cut of the metal is carried out. At the same time the speed of operation is quite high, which is an indisputable plus during the cutting of large quantities of metal. It is important that the cost of such a method of metalworking, to put it mildly, is profitable. It is several times lower than other methods, which require a lot of work and a lot of time.

Advantages of laser cutting

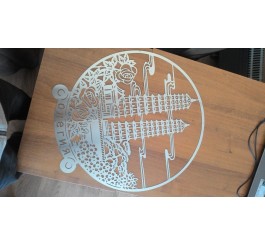

Laser cutting can be not only ordinary, but also figurative or artistic. With its help you can easily create details of the most interesting form. This technology has a lot of advantages that make it popular and accessible to a wide range of consumers. The main advantages of this type of metal working are:

- minimum thickness of the cut;

- absence of mechanical contact with the material;

- high speed of cutting thin-gauge steel;

- possibility of cutting any level of complexity;

- the edges of the cut often do not require additional processing, since they do not have troughs;

- the possibility of processing metals from hard alloys;

- control of the cutting process is carried out using a special software package that can withstand errors in very small quantities;

- low cost.

-

Services of laser cutting of metal from ZTO "Olegiya"

Laser cutting is a universal way of processing metal. It allows you to achieve high results with the least amount of time and money. Our enterprise performs cutting of materials according to customer sketches or specified contours. The thickness of the processed metal is:

- for stainless steel - 0-4 mm;

- for black metal - 0-4 mm.

As an auxiliary gas, we use nitrogen or oxygen. It should be noted that cutting metal in a nitrogen environment prevents the oxidation and corrosion process, and also protects the material from the thermal action of the laser. This technology of cutting complex alloys is the most popular and effective. The use of oxygen in laser cutting is necessary to increase the processing speed of metal and increase the temperature in the cutting zone. This is important when cutting high-strength materials, and in particular, carbon steel.

You can order this service by contacting our managers who will tell you all the details: the lead time and cost. The price of the service is formed based on the complexity of the work and the thickness of the metal. We responsibly approach the fulfillment of the set tasks, and also, we guarantee the efficiency and high quality of the service!

-265x245.jpg)